CNC Machining

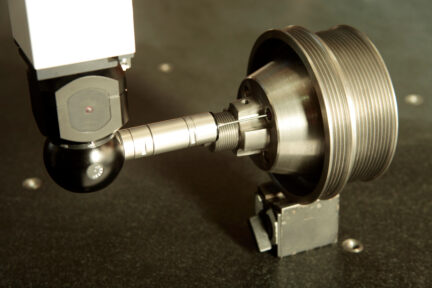

B&B Dynamic Machining specializes in computer numerical control (CNC) machining for commercial and consumer applications. CNC machining lends your projects the benefit of faster, high-quality manufacturing that optimizes efficiency, product consistency, and throughput. We utilize 3- and 4-axis CNC mills and a CNC lathe to achieve precision parts with tight tolerances of ±0.0005.

We work closely with you from the prototyping stage through production, taking your designs and bringing them to life as precision parts with on-time delivery. Depending on the complexity of your project, typical lead times at B&B are four to eight weeks.

Machines Used:

- Haas VF-2

- 30” x 16″ x 20″

- 8000rpm

- Haas VF-4 with Rotary

- 50″ x 20″ x 25″

- 15,000rpm

- Topper CNC lathe with 10″ chuck

To provide optimal versatility, our CNC operations include the following for low- and medium-volume production runs:

- Milling

- Turning

- Profiling

- Boring

- Drilling

- Countersinking

- Cutting

- Facing

- Pocketing

- Threading

- Knurling

- Reaming

Our processes are compatible with a broad spectrum of metal, alloy, superalloy, plastic, and synthetic material options. We work with:

- Aluminum

- Brass

- Cobalt

- Copper

- Steel and stainless steel

- Hastelloy®

- Inconel®

- Monel®

- Stellite®

- ABS

- PEEK

- PTFE

- PVC

- PVDF

- Acetal

- Acrylic

- Nylon

- Phenolic